.png)

When it comes to safety, today’s warehouses are really between a rock and a hard place. On the one hand, having frequent safety meetings has never been more important, because there are so many new...

“500” Reasons To Use These March 2020 Driver Safety Meeting Topics A few weeks ago, many of us watched in horror as Ryan Newman’s car suffered a potentially lethal crash during the last lap of the...

March 2020 Warehouse Safety - What’s Luck Got To Do With It? Raise your hand if you believe in leprechauns. How about the magic of four-leaf clovers? “Lucky” subjects like that are fun to think about...

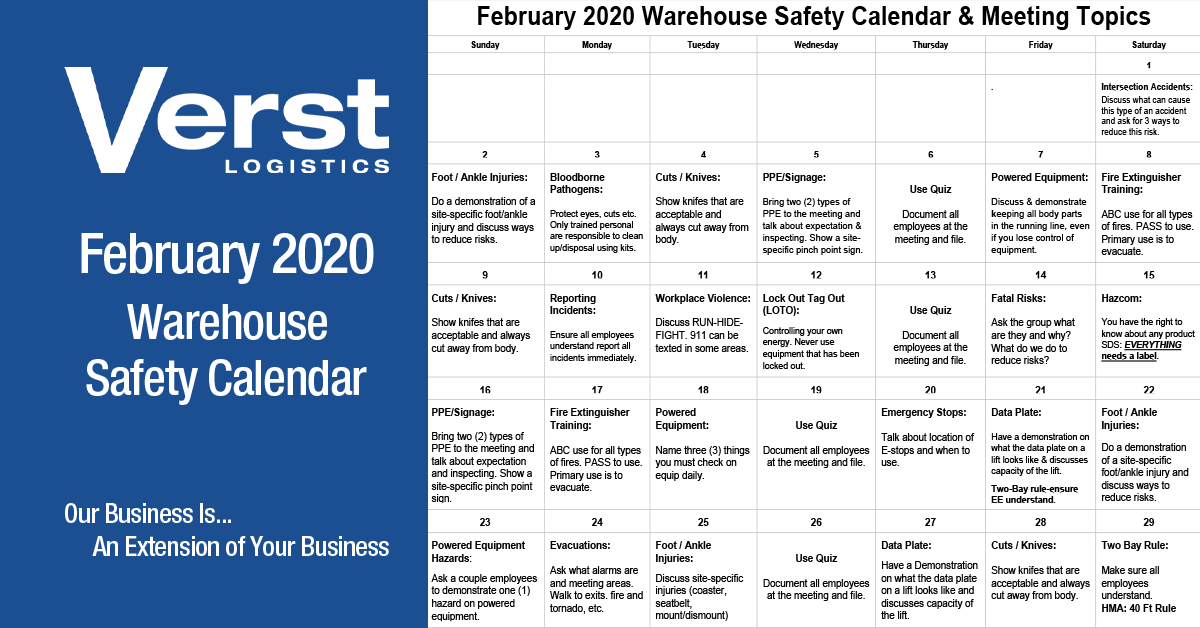

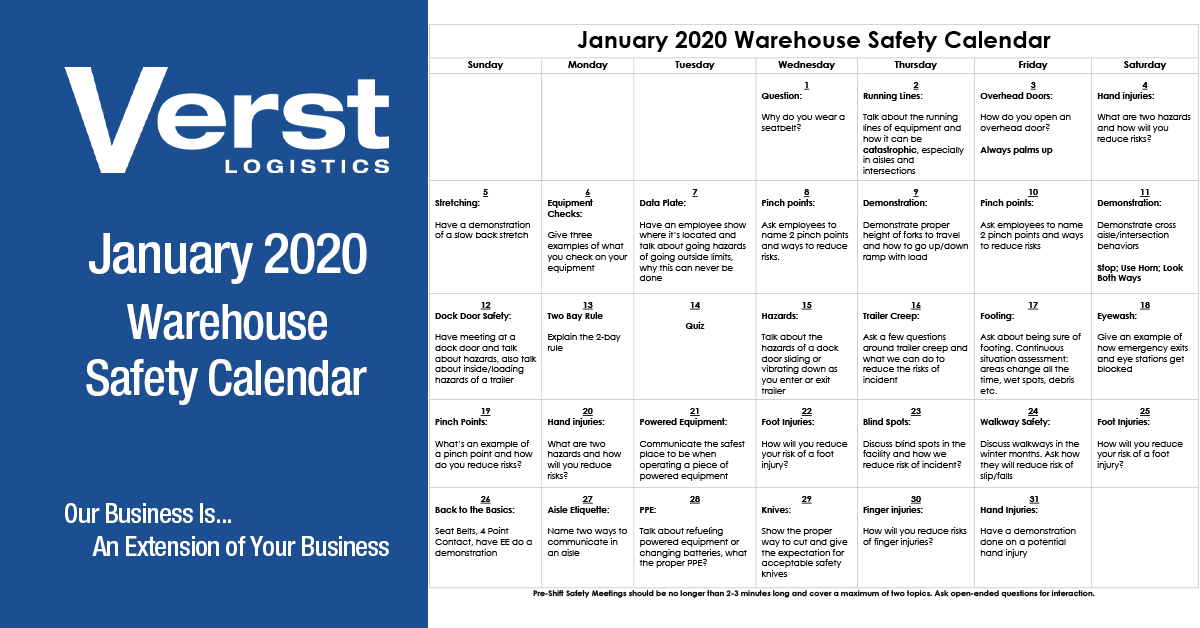

29 Ideas For February Risk-Prevention Discussions: A Day-to-Day Warehouse Safety Calendar When most people think of risky careers, becoming a warehousing professional probably isn’t one of them. Yet...

Safety must always be a top priority because warehouses are of the most dangerous places to work in America. But how can those risks be mitigated in order to keep employees safe and to keep the...

There was a time when holiday returns were limited to things like that “adorable” sweater your Aunt Edna bought you – or that ultra-loud toy some well-meaning relative bought your kids Not anymore....

Once upon a time, there was a company that had 100% customer satisfaction. Its customers didn’t just love its products, they loved its fulfillment – and they frequently posted positive things about...

By this point in the peak season, most of us who work in fulfillment need an extra sales surge about as much as we need a hole in the head. After all, order volumes are already at their highest and...