July 30, 2018

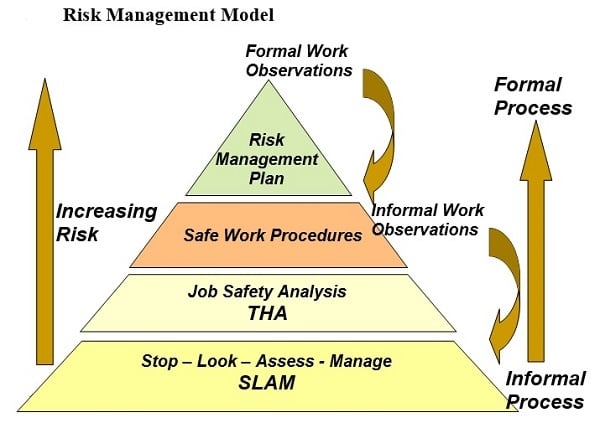

Safety systems are used to proactively manage risk to As Low As Reasonably Possible (ALARP). ALARP is achieved by using: Personal experiences, Other’s experiences, Good work practices, Rules and Procedures, and Regulations. It is important that the organization have the knowledge, skill and the will and energy to consistently use these systems. The quality of safety systems and the effectiveness of using safety systems is a key driver in managing risk to ALARP and achieving “Zero Harm”. Each Safe Operations System is described below.

Purpose / objective

To recognize the hazards created through the interaction of people, machine and the environment and manage these hazards to achieve ALARP.

Process:

Key Measurement

All work is planned with risk assessment and work is accomplished to ALARP

Purpose / Objective

To provide a more formal risk management system for work activities with higher risk, more complexity or requiring consistency.

Process:

Key measurement

THA and procedures are routinely used, formally audited, and updated.

Purpose / Objective

To share experiences where risk was not managed to ALARP; whether an actual incident or near-miss. The organization uses this information to plan work with risk assessment.

Process:

Key measurement

The organization plans work differently and the incident does not re-occur.

Purpose / Objective

To routinely provide the organization information of how to mange workplace hazards to achieve ALARP

Process:

Key measurement

The organization utilizes information to plan work and manage hazards to ALARP

Purpose / Objective

To conduct in-field audits / discussions so the organization understands objectives, boundaries are clarified, good behaviors are reinforced, corrections are made as necessary, and systems are assessed

Process:

Key measurement

The line management spends 15 – 60% of time in the workplace focusing on proactive activities to achieve Safe Operations. The organization is at ease in sharing and working together to continually improve Safe Operations.

Purpose / Objective

To conduct a Safe Operations leading indicator audit to benchmark progress in achieving the key elements of Safe Operations and identify opportunities for improvement.

Process:

Key measurement

The line organization continues to make progress in achieving Safe Operations as measured by the audit elements. The objective will be to have no facility below 2.8.

Purpose / Objective

The organization clearly understands boundaries, is trained effectively and applies good judgment to stay within the boundaries of Safe Operations

Process:

Key measurement

The organization motivate themselves toward accomplishing objectives because of beliefs, principles, personal and organizational needs.

Purpose / Objective

To develop people so that the individual achieves expectations beyond minimum job expectations

Process:

Key measurement

The organization demonstrates caring and support, improved capability and continually improving Safe Operations measurements.

Purpose / Objective

The manager’s presence is felt in a way that the organization responds positively to the manager’s direction and achieves peak performance

Process:

Key measurement

The organization is energized and is achieving Safe Operations along with other business success factors.

Tags:

Packaging , Fulfillment , Warehousing , Safety , Verst News

Safe Operations requires that all key elements of the operations (safety, productivity, cost management, environmental, human relations, etc) be done and done well. Safety, quality and production...

Resources

Connect