April 28, 2023

Supply Chain professionals at Verst Logistics are predicting what warehouses of the future will have.

We’re looking into our logistics crystal ball and predicting features, processes and technology that warehouses of the future will have, especially in the realm of dedicated and contract warehousing. Read on to discover what the Verst Supply Chain Experts see on the horizon!

1. Feature for the Future: TechnologyAt Verst, we have made significant investments in cutting-edge fulfillment warehouse technology to empower our clients now and into the future. This same kind of forward-thinking approach will shape our warehouses in the future. Here are a few ways new technology will continue to transform the warehouse of the future:

Blockchain. Overall, blockchain has the potential to significantly transform the dedicated warehousing industry by improving transparency, efficiency, security, and automating many of the manual tasks involved in managing inventory. As the technology continues to mature, we can expect to see more innovative solutions and applications in this space.

Artificial Intelligence and Robotics. By interconnecting these two rapidly advancing technologies, artificial intelligence enables warehouse activities to be performed with greater speed and accuracy. This enables machines to simulate human-like behavior and decision-making. At Verst, Locus Robotics’ system-guided robots inside our contract and dedicated warehouses work alongside Verst employees to assist with picking and packing, resulting in greater overall productivity and 99.7% order accuracy.

Automation. According to Supply & Demand Chain Executive, 80% of warehouses haven’t invested in automation. Industry experts predict a huge increase in adoption of automation technologies over the next 5 years, driven by the ongoing labor shortage, a need for more integrated fulfillment warehouses, and the introduction of better performing, more affordable solutions.

2. Feature for the Future: Sustainability / Social Responsibility / Safety and Security

Prioritizing sustainability, social responsibility, safety, and security considerations will shape the future of dedicated and contract warehousing. By prioritizing these key aspects, warehouses can adopt more effective, environmentally friendly, and socially conscious practices while simultaneously maintaining robust safety and security measures. Here are some potential impacts of these factors:

Recycling & Responsible Waste Disposal. To achieve sustainability goals, one area that requires increased attention is recycling and responsible waste management. Key issues like going paperless, minimizing packaging, and using more eco-friendly materials for packaging, are required for responsible warehouses responding to the need for greater sustainability.

Energy use. Currently, fulfillment warehouses generate 10% of the total logistics and supply chain CO2 emissions. Minimizing energy consumption and reducing the costs associated with it are becoming more vital. An increase in real-time energy monitoring and management to identify energy usage patterns, highlight areas of waste quickly, so that corrective action can be taken. Lighting controls like motion sensors, daylight sensors and timers help to greatly reduce energy usage too.

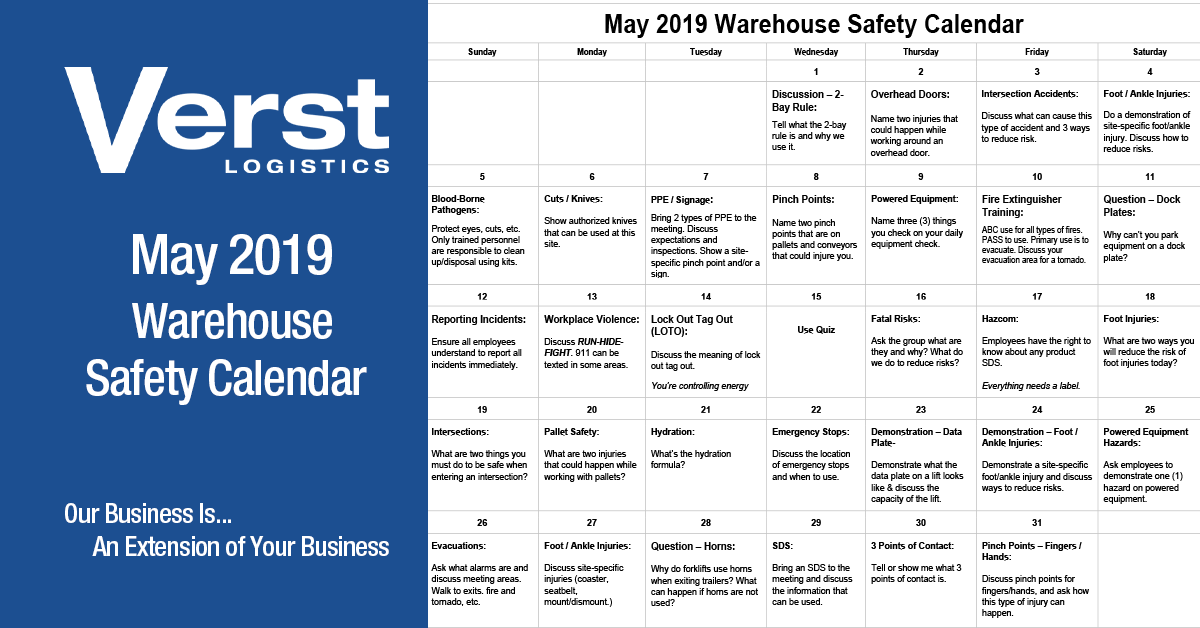

Safety & security. Dedicated warehouse safety is one of the most important parts of the storage and logistics industry. The same technological advances we mentioned above will be used to keep workers safe. Our experts predict that RFID sensors, virtual reality, automation and even drones will be increasingly used in warehouses to keep workers safe. For instance, RFID tags and sensors can send proximity warnings if a worker strays too close to an unsafe area. AMRs and drones perform tasks that are unsafe for human employees or repetitive tasks that reduce the potential for repetitive strain injuries.

At Verst, AMRs are already in place, and Verst is already taking the lead in other ways as well. Mike Hart, VP of Risk Management at Verst, said, “We piloted a cutting-edge program that uses camera software to seek out incorrect behaviors. It automatically sends an alert to managers. Managers can then counsel the employee on correct procedures. The pilot program was so well received, we are implementing it at a second facility.”

Community support, employee engagement, training and retention. The warehousing industry will need to consider its social responsibility to employees, customers, and the wider community. This could involve implementing fair labor practices, investing in employee training and development and supporting local communities through charitable initiatives.

3. Feature for the Future: Consumer product customizationsCustomizing products and packaging within the four walls of a contract or dedicated warehouse has become increasingly popular in recent years, thanks in large part to the rise of e-commerce and customer expectations. With the growth of online shopping, consumers have come to expect highly responsive and personalized service, and customized products and packaging can be a keyway to meet those expectations.

Why Verst for Dedicated Warehousing?

With 27 warehouses totaling over 7.8 million square feet of space, Verst provides design and management of warehouses and cross-docks—while providing a full range of value-added services such as packaging, kitting and customization. Verst’s Dedicated Warehousing and Contract Logistics management team has a deep understanding of the operational needs required to successfully manage an operation from start to finish.

Need advice for an exceptional Dedicated Warehousing solution from our team? Visit us online or call our warehousing experts at 800-978-9307.

Tags:

Warehouses are statistically one of the most dangerous places to work, and the added tasks of operating heavy machinery and transporting large objects do not make it safer. In 2017, there were...

Warehouses are statistically one of the most dangerous places to work, and the added tasks of operating heavy machinery and transporting large objects do not make it safer. In 2017, there were...

Resources

Connect