July 23, 2018

Why do companies rent warehouse space and how much does it cost?

Most companies do not have an anticipated requirement of space or labor, while the volume of products differentiate for many diverse reasons - the season, the economy, the trendiness of a product, etc. Instead of investing a massive amount of capital to build a warehouse, companies choose to use 3PLs to be their warehousing partner because they can offer transnational rates that are variable where distribution costs coincide with their revenue streams.

For example, think of a parking garage - you can pay hourly, daily, monthly, or yearly. The amount of time you stay is what you are charged for taking up the space for that time period. As you can see, the price for hourly versus daily and monthly are going to greatly differ. With warehousing pricing, the concept works the same, but you pay for the service as they are needed.

It would be great if getting warehouse storage pricing was the same as going to a mass merchandiser and getting the same price at every location in the United States, right? Unfortunately, warehousing pricing doesn't work that way, but it is a very smart idea for shippers to be knowledgeable regarding pricing. This way, you will get an accurate quote by providing as much detailed information as possible.

Different 3PLs have varying pricing methodologies so they do not always account for the costs the same way, which makes it difficult for a direct comparison of the companies' pricing. This post will show you exactly what goes into warehousing pricing by 3PLs and how you lower your rate by the way your product is stored and handled.

Warehousing pricing depends on the amount of space and time it takes to perform certain tasks. But, this can get complicated. Tasks can be performed with or without automation, with or without computer systems, with or without engineered process flows - all of these things affect the time aspect of pricing. And products can be stored in different ways – unstacked on the floor, stacked several levels high on the floor, or in racks as high and as deep as the building and business profile will allow. The storage method will dramatically impact space required and ultimately, the storage rate.

Detailed information is required to determine how much space and labor will be required.This is why it is critical to be as detailed as possible when getting a quote because then it will be very accurate. Lets get into the pricing detail and then we will discuss ways to reduce costs on your quote.

Factors that go into pricing

Tags:

Just like with marriage, companies are seeking long-lasting relationships with their "other half." In today's battle of who can deliver products the quickest and the competition heating up to even...

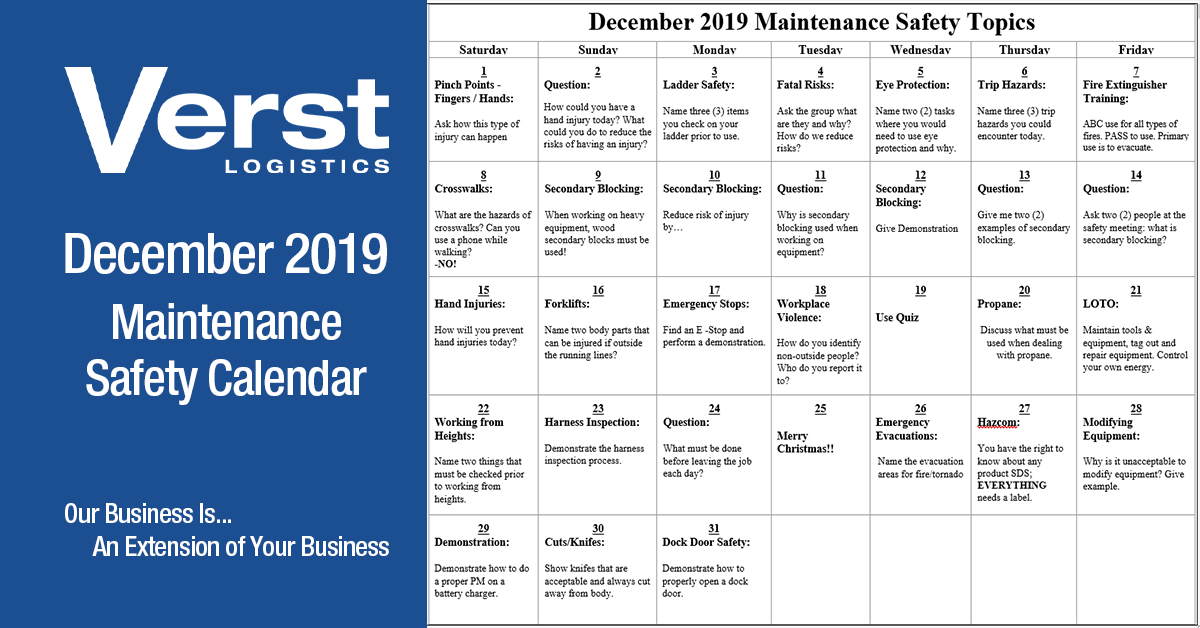

Regular maintenance is required to keep all equipment, machines and the work environment safe and reliable at all times in the warehouse. Dangerous situations, accidents and health problems can occur...

Resources

Connect