September 20, 2018

Verst Logistics has been servicing logistics customers since 1966, with a number of partnerships lasting 20+ years. With that in mind, and given our collaborative history with several major brands, this blog post covers the recent trends in outsourcing versus insourcing warehousing. We value our partnerships and believe it is our responsibility to provide support and assistance to our partners when considering strategic logistics options.

Warehousing and distribution strategy is an increasingly critical aspect of business. Choosing whether to insource or outsource will play a key role in your growth potential.

When developing your strategy, a 3PL warehouse provider gives you access to an entire spectrum of supply chain & logistics expertise. For small startup companies looking to establish a presence in a strategic market or large companies looking to seize opportunity in new areas, and any others in between, third party logistics providers give options that allow businesses to scale efficiently.

Does it make sense for your business to outsource? Below in an in-depth analysis as to why you should or should not outsource some, if not all, of your distribution to a 3PL provider.

Why Should Your Company Outsource

Cost reduction is one of the main reasons why many organizations decide to outsource in today's society, but there has been a shift in the reasons, and they widely vary, even beyond dollar signs. This can be attributed not only to the degree of complexity and velocity of the company's supply chain, but the expectations and demand of the consumer as well.

Top 5 Reasons Why Your Company Should Outsource

When using a 3PL distribution provider, this move will allow the flexibility for you to set up and scale your distribution model as business demands shift. In doing so, you can more easily grow into new markets that allow you to service new and diverse customer bases.

Here are three examples of flexibility from outsourcing:

A 3PL will provide a variety of value-added activities, such as:

Leveraging a third-party logistics provider for their operational process expertise, and know-how within your industry are strategic advantages realized by outsourcing. Outsourcing reduces your costs, drives up your efficiency and allows you to focus on your core business, as a 3PL provider will:

Warehouse Management Systems (WMS), Transportation Management Systems (TMS), Radio Frequency Identification (RFID) and Electronic Data Interchange (EDI) integration capabilities are all technology solutions that add supply chain visibility & connectivity, create efficiency and streamline supply chain processes. Large distributors often provide barriers to small or less sophisticated companies due to data and information transmission requirements. The big box retailers of the world no longer have to be off-limits for companies of any size.

Powerful WMS and TMS capabilities can add huge value to your company. These systems allow for real-time access to detailed inventory information and allow you to forecast upcoming trends. Leveraging a 3PL that has strong technological capabilities allows you to leverage their systems and expertise to improve logistical processes. Taking it to the next level – integrating supply chain information into your own business systems provides larger scale insights to how your business is ultimately serving your customer.

Cost savings can be realized in many ways, however the most common of which involves process and people.

PROCESS:

PEOPLE:

A 3PL provider gives you ability to easily forecast the landed cost of each of your products and account for this in your sales process. This is real example of how a 3PL provides cost savings.

A fully integrated 3PL warehousing and distribution strategy allows you to utilize an expert to manage your supply chain. A 3PL provider should be able to provide a road map to how you can most effectively build and maintain your supply chain. The provider should be rooted in providing flexible solutions that fit your strategy, technology that allows you to scale efficiently, and process development to drive efficiency and cost reduction, and have the fiscal sense to help you maximize your transportation dollar. Contact us to learn more about options for outsourcing warehousing and distribution.

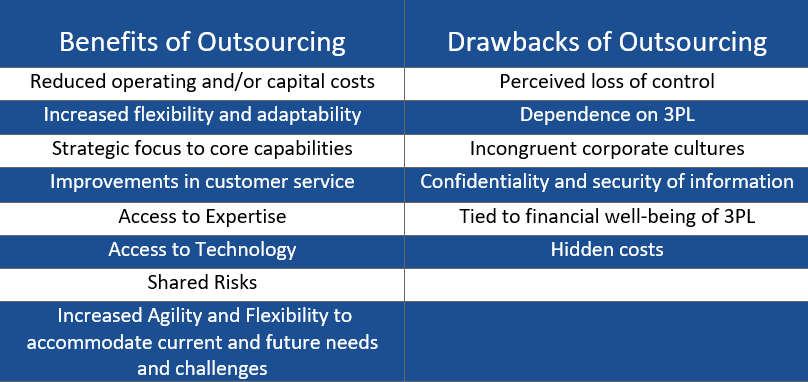

Benefits/Drawbacks of Outsourcing

The benefits and drawbacks of outsourcing are directly related to the relationship between the company and its 3PL logistics provider. Successful outsourcing arrangements are typically well defined, planned and executed when there is a level of shared trust, collaboration and integration between both parties.

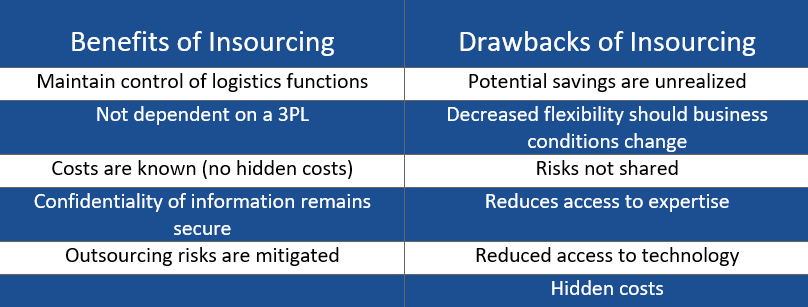

Reasons Why Companies Chose To Insource

While the general trend among companies is to increase their use of outsourced logistics services, there are also companies who choose not to outsource and maintain control of their supply chains internally (insourcing). Typically, companies choosing to insource have very complex supply chains with significant regulatory, political and customer challenges. While less prevalent, companies choosing to insource typically do so for the following reasons:

Benefits/Drawbacks of Outsourcing

Tags:

Are you searching for product fulfillment solutions? Most businesses depend on effective product fulfillment. If you regularly ship out products to your customers, those customers likely depend on...

Just like with marriage, companies are seeking long-lasting relationships with their "other half." In today's battle of who can deliver products the quickest and the competition heating up to even...

Resources

Connect