November 29, 2019

Regular maintenance is required to keep all equipment, machines and the work environment safe and reliable at all times in the warehouse. Dangerous situations, accidents and health problems can occur as a result of not conducting proper maintenance checks.

With maintenance, some hazards in the warehouse are formed as a result of the nature of the work since it is a high-risk activity. Maintenance workers are more likely than other employees to be exposed to various hazards.

Warehouse maintenance poses specific hazards and risks to those working alongside a running process and in close contact with machinery. During normal operation, automation typically diminishes the likelihood of human error that can lead to accidents. In maintenance activities, contrary to normal operation in a warehouse, direct contact between the worker and machine cannot be reduced substantially and poses a greater risk of human error. This, in turn, increases the accident risk because maintenance is an activity where the workers need to be in close contact with processes.

In 2018 alone, according to the U.S. Department of Labor Statistics, there was over 29,000 days spent away from work by maintenance workers as a direct result of an accident. In 2018, warehouse and transportation workers had 30,080 medical treatment facility visits, 26490 emergency room visits and 3,590 in-patient overnight hospitalizations.

Warehouse maintenance often involves unusual work, non-routine tasks and it is often performed in exceptional conditions, such as working in confined spaces.

Maintenance in a warehouse involves changing tasks and working environment. This is especially true in case of contract workers. Subcontracting is an aggravating factor in terms of safety and health - numerous accidents and incidents relate to subcontracting maintenance.

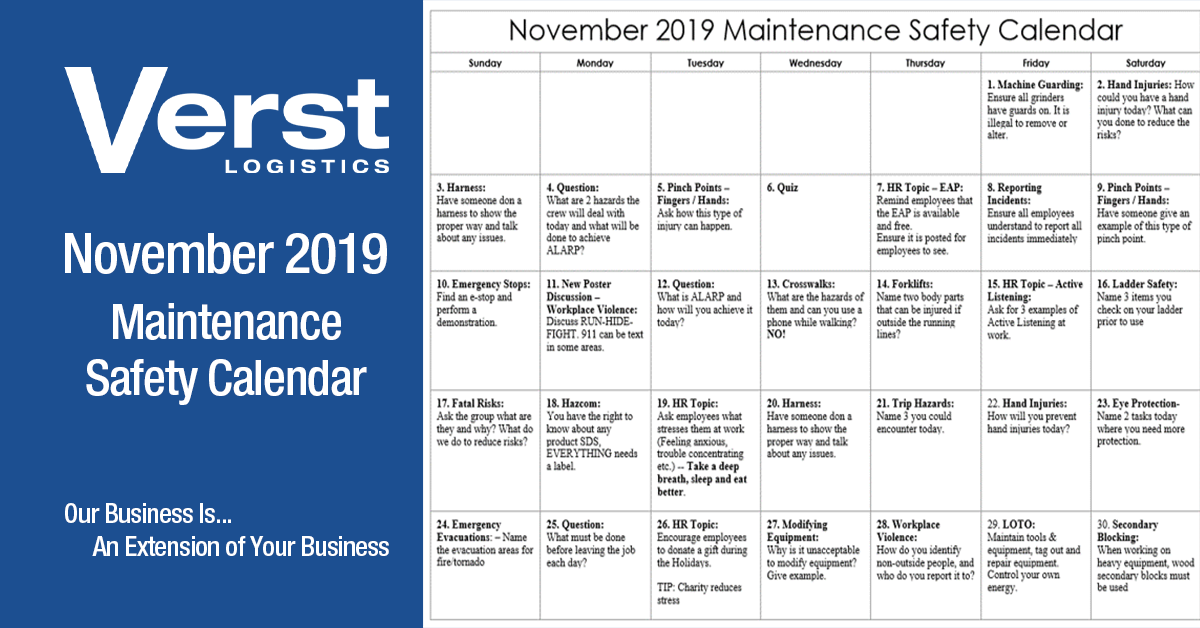

Since maintenance safety in warehouses is a big factor in decreasing risks in the workplace, we have created the following safety calendar that will help guide you through daily safety discussions with your employees. Feel free to use this calendar and our other calendars to operate a safer work environment.

Be sure to check out our safety blog for the latest, tips, tricks, and safety lessons below.

Download the calendar here: December 2019 Maintenance Safety Calendar

December 2019 Maintenance Safety Calendar |

|

Sunday |

Monday |

Tuesday |

Wednesday |

Thursday |

Friday |

Saturday |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

Pinch Points -Fingers / Hands: Ask how this type of injury can happen. |

Question: How could you have a hand injury today? What could you do to reduce the risks of having an injury? |

Ladder Safety: Name three (3) items you check on your ladder prior to use. |

Fatal Risks: Ask the group what are they and why? How do we reduce risks? |

Eye Protection: Name two (2) tasks where you would need to use eye protection and why. |

Trip Hazards: Name three (3) trip hazards you could encounter today. |

Fire Extinguisher Training: ABC use for all types of fires. PASS to use. Primary use is to evacuate. |

|

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

Crosswalks: What are the hazards of crosswalks? Can you use a phone while walking? -NO! |

Secondary Blocking: When working on heavy equipment, wood secondary blocks must be used! |

Secondary Blocking: Reduce risk of injury by… |

Question: Why is secondary blocking used when working on equipment? |

Secondary Blocking: Give Demonstration |

Question: Give me two (2) examples of secondary blocking. |

Question: Ask two (2) people at the safety meeting: what is secondary blocking? |

|

15 |

16 |

17 |

18 |

19 |

20 |

21 |

|

Hand Injuries: How will you prevent hand injuries today? |

Forklifts: Name two body parts that can be injured if outside the running lines? |

Emergency Stops: Find an E -Stop and perform a demonstration. |

Workplace Violence: How do you identify non-outside people? Who do you report it to? |

Use Quiz |

Propane: Discuss what must be used when dealing with propane. |

LOTO: Maintain tools & equipment, tag out and repair equipment. Control your own energy. |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

|

Working from Heights: Name two things that must be checked prior to working from heights. |

Harness Inspection: Demonstrate the harness inspection process. |

Question: What must be done before leaving the job each day? |

Merry Christmas!! |

Emergency Evacuations: Name the evacuation areas for fire/tornado. |

Hazcom: You have the right to know about any product SDS; EVERYTHING needs a label. |

Modifying Equipment: Why is it unacceptable to modify equipment? Give example. |

|

29 |

30 |

31 |

|

|

|

|

|

Demonstration: Demonstrate how to do a proper PM on a battery charger. |

Cuts/Knifes: Show knifes that are acceptable and always cut away from body. |

Dock Door Safety: Demonstrate how to properly open a dock door. |

|

|

|

|

Tags:

Regular maintenance is required to keep all equipment, machines and the work environment safe and reliable at all times in the warehouse. Dangerous situations, accidents and health problems can occur...

Resources

Connect