October 17, 2018

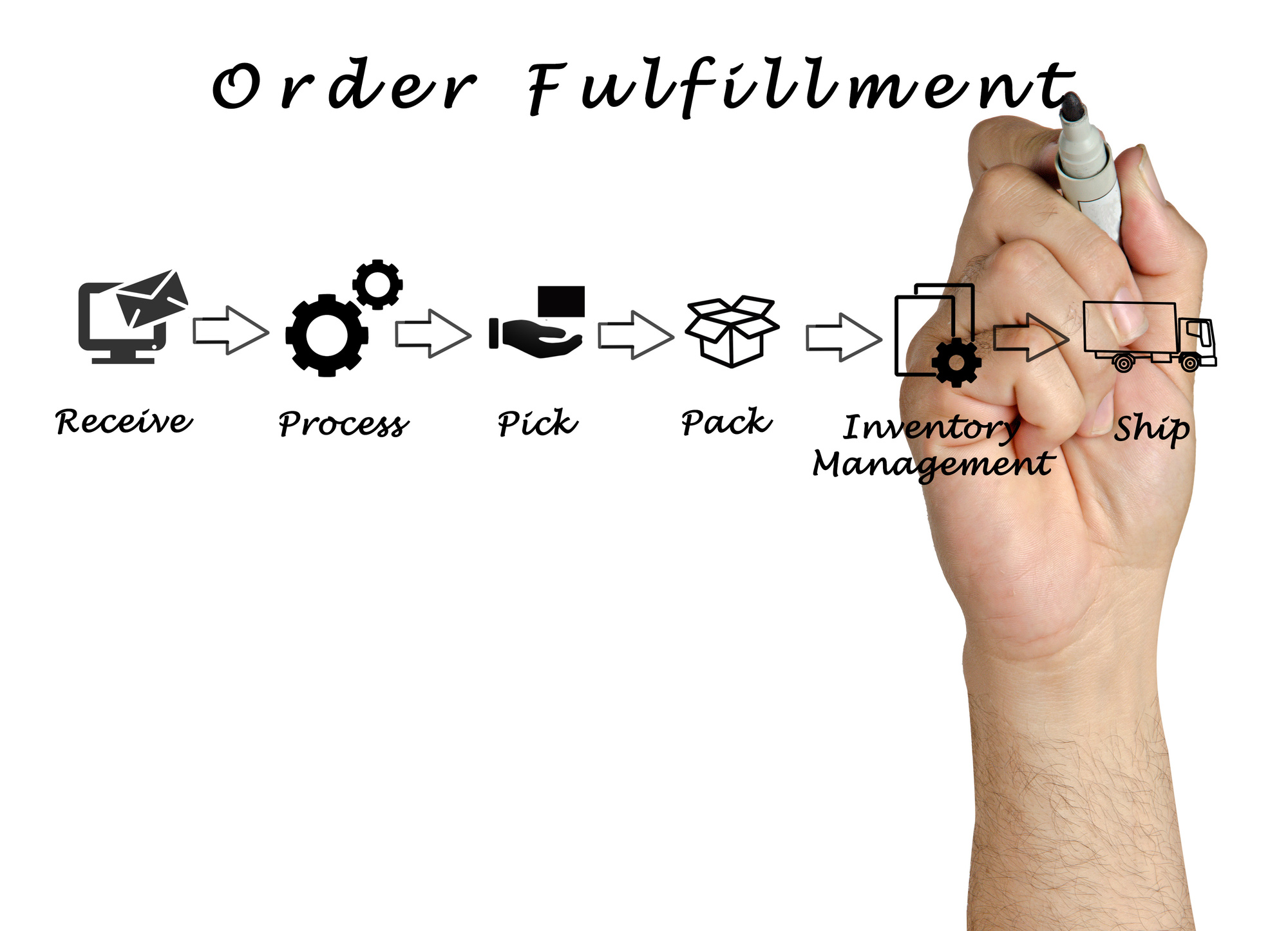

Key performance indicators are a major tool in measuring the success (or failure) of your operation. When we look at order fulfillment for the retail industry, there are major metrics that a company should monitor in order for to evaluate their fulfillment operations. Over the course of this blog post, we will discuss the top four (4) most important KPIs for a retail company to track to best evaluate the performance of their order fulfillment service. We will also discuss why these KPIs are important to your company as well.

Whether you're utilizing a 3PL or keeping your order fulfillment in-house, the top four (4) KPIs that you need to monitor are:

But, what exactly do these KPIs mean for you and your customers?

Order accuracy refers exactly to getting out the correct order that the customer ordered. Retail operations managers should care how accurately these orders are being sent out because getting an order wrong can be very costly. Also, you could lose all future business entirely with a customer because of a wrong order. See our blog post about issue resolution here.

Inventory accuracy refers to how the inventory is tracked and references the amount of physical inventory in stock in your warehouse versus what the book says. This is an important metric for demand planning and the shift in seasonal markets. The last thing that retail operations crews want is to have stockpiles of very slow-turning inventory that is costing them lots of space and revenue. See our blog post here.

The next KPI that is important to measure is receiving speed, which refers to when product arrives at the facility and the turnaround time for the product to be put away, stored, and available in the ordering system for the retail merchant to sell. This metric not only affects the merchant, but also the end customer as well. Customers who are ordering trending items may receive their item in more time than expected if the shipments are not turned around quickly, resulting in a dissatisfied customer. This discontent may lead the customer to shop elsewhere in the future. See our blog post about demand planning and how to avoid this problem here.

The final KPI that must be monitored is shipping timeliness, which refers to how quickly the company receives the order to how much time it takes to get the order sent out and on its way to the customer. The slower the transition time, the longer it takes for a customer to receive an item they purchased. With the fulfillment norm being 2-day shipping, anything outside of this window may make a customer seek a new alternative provider. See our blog post about the importance of reaching your customers in two days or less here.

But the question is, how do you track these KPIs? With the integration of technology into warehouses nowadays, it is easier than ever before. Radio frequency scanning and warehouse management systems (WMS) have the ability to monitor these KPIs in real-time speed so retail companies can push the KPIs out to their customer. For example, if a company knows with 99% accuracy that they can get an item delivered to any part of the U.S. in 2 days or less, they will want to tell that to their customer base.

With today's shift to a more technologically sound world, other metrics to be monitored include labor productivity and how efficient your operations are today. Companies should be focused on optimizing their labor and the number of employees that are needed to most efficiently run an operation by focusing on the data given from the KPIs.

Tags:

Are you spending way too much on order fulfillment? Order fulfillment involves the costs and processes associated with shipping and handling. To stay competitive, it's vital for businesses to fulfill...

Are you searching for product fulfillment solutions? Most businesses depend on effective product fulfillment. If you regularly ship out products to your customers, those customers likely depend on...

Resources

Connect