May 1, 2019

Warehouses are statistically one of the most dangerous places to work, and the added tasks of operating heavy machinery and transporting large objects do not make it safer. In 2017, there were approximately 209,000 non-fatal occupational injuries in the transportation and warehousing industry in the private sector according to the U.S. Bureau of Labor. The even bigger number is the days away from work that still costs company's money when the employee isn't present. In 2017 alone, there were over 20,000 days away from work related to injuries by warehouse workers.

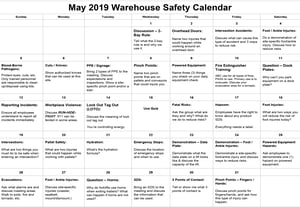

Download the safety calendar here: May 2019 Warehouse Safety Calendar

Warehouse injuries are extremely expensive, and needless to say because of this, warehouse safety is extremely important.  The even bigger reason to focus on safety is the well-being of your employees - they need to come first. There are many things you can do to avoid workplace accidents and to maintain a safe workplace for your employees and the environment. It is important to establish a proper safety protocol, conduct regular safety training, follow long-term and short-term housekeeping procedures, and have the proper safety products and equipment.

The even bigger reason to focus on safety is the well-being of your employees - they need to come first. There are many things you can do to avoid workplace accidents and to maintain a safe workplace for your employees and the environment. It is important to establish a proper safety protocol, conduct regular safety training, follow long-term and short-term housekeeping procedures, and have the proper safety products and equipment.

Please use this monthly safety calendar to go over topics with your employees that will allow your managers to establish proper warehouse safety protocol and conduct regular daily and monthly warehouse safety training schedules.

Please use our monthly warehouse safety calendar below as a guide for your safety meetings.

May 2019 Warehouse Safety Calendar |

||||||

| Sunday | Monday | Tuesday | Wednesday | Thursday | Friday | Saturday |

|

|

|

|

1 |

2 |

3 |

4 |

|

|

|

|

Discussion – 2-Bay Rule: Tell what the 2-bay rule is and why we use it.

HMA: 40 feet |

Overhead Doors: Name two injuries that could happen while working around an overhead door. |

Intersection Accidents: Discuss what can cause this type of accident and 3 ways to reduce risk. |

Foot / Ankle Injuries: Do a demonstration of site-specific foot/ankle injury. Discuss how to reduce risks. |

|

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

Blood-Borne Pathogens: Protect eyes, cuts, etc. Only trained personnel are responsible to clean up/disposal using kits. |

Cuts / Knives: Show authorized knives that can be used at this site. |

PPE / Signage: Bring 2 types of PPE to the meeting. Discuss expectations and inspections. Show a site-specific pinch point and/or a sign. |

Pinch Points: Name two pinch points that are on pallets and conveyors that could injure you. |

Powered Equipment: Name three (3) things you check on your daily equipment check. |

Fire Extinguisher Training: ABC use for all types of fires. PASS to use. Primary use is to evacuate. Discuss your evacuation area for a tornado. |

Question – Dock Plates: Why can’t you park equipment on a dock plate? |

|

12 |

13 |

14 |

15 |

16 |

17 |

18 |

|

Reporting Incidents: Ensure all employees understand to report all incidents immediately. |

Workplace Violence: Discuss RUN-HIDE-FIGHT. 911 can be texted in some areas. |

Lock Out Tag Out (LOTO): Discuss the meaning of lock out tag out. You’re controlling energy |

Use Quiz |

Fatal Risks: Ask the group what are they and why? What do we do to reduce risks? |

Hazcom: Employees have the right to know about any product SDS. Everything needs a label. |

Foot Injuries: What are two ways you will reduce the risk of foot injuries today? |

|

19 |

20 |

21 |

22 |

23 |

24 |

25 |

|

Intersections: What are two things you must do to be safe when entering an intersection? |

Pallet Safety: What are two injuries that could happen while working with pallets? |

Hydration: What’s the hydration formula? |

Emergency Stops: Discuss the location of emergency stops and when to use. |

Demonstration – Data Plate- Demonstrate what the data plate on a lift looks like & discuss the capacity of the lift. |

Demonstration – Foot / Ankle Injuries: Demonstrate a site-specific foot/ankle injury and discuss ways to reduce risks. |

Powered Equipment Hazards: Ask employees to demonstrate one (1) hazard on powered equipment. |

|

26 |

27 |

28 |

29 |

30 |

31 |

|

|

Evacuations: Ask what alarms are and discuss meeting areas. Walk to exits. fire and tornado, etc. |

Foot / Ankle Injuries: Discuss site-specific injuries (coaster, seatbelt, mount/dismount.) |

Question – Horns: Why do forklifts use horns when exiting trailers? What can happen if horns are not used? |

SDS: Bring an SDS to the meeting and discuss the information that can be used. |

3 Points of Contact: Tell or show me what 3 points of contact is. |

Pinch Points – Fingers / Hands: Discuss pinch points for fingers/hands, and ask how this type of injury can happen. |

|

Tags:

Warehouses are statistically one of the most dangerous places to work, and the added tasks of operating heavy machinery and transporting large objects do not make it safer. In 2017, there were...

Resources

Connect