February 28, 2020

Raise your hand if you believe in leprechauns. How about the magic of four-leaf clovers?

“Lucky” subjects like that are fun to think about when March and St. Patrick’s Day roll around. But few of us would ever seriously consider using them as a solid business strategy.

That said there are many professionals who clearly do believe in luck, because they rely on it every day.

We’re talking about warehouse managers and supervisors. More specifically we’re talking about the ones who think that they don’t need to put much effort into safety training because, “Our facility hasn’t had any serious accidents or injuries lately.”

On the one hand, we can see their point. After all, it’s easy to assume you must be doing really well at safety if your facility has been practically perfect.

On the other, that doesn’t change a few harsh realities:

The first is that your employees may not be reporting every OSHA-recordable incident to you, especially if your facility has been making a big deal about being a billion days accident-free. (After all, who among us wants to be the one to break the impressive streak?) Just ask the intern at a 3PL facility who found herself on the wrong side of a rusty nail. Instead of reporting it to her shift manager, she just called her mom to make sure her tetanus shot was up to date and then went on working. So as far as that facility’s management knows (and for the record, that facility wasn’t one of ours), it’s STILL accident-free, even though it really isn’t.

The second is that warehouses are inherently risky places to work. Even at their best, they contain a potentially dangerous combination of heavy equipment, perpetual motion and aggressive deadlines. Mix that with numerous human beings who may occasionally get distracted or make mistakes, and you have an ideal breeding ground for injury – or worse.

This explains why even companies with the industry’s most amazing safety records have at least some OSHA-recordable injuries and why even facilities that have gone a super-long time without an incident will eventually have that perfect streak broken.

In fact, much like Indianapolis 500 drivers reportedly say there are two kinds of competitors – those who have hit the wall and those who will – there are many who believe a similar expression pertains to forklift drivers and other warehouse employees, because the risk of accident or injury goes with the territory.

The moral of this story is pretty simple: No matter how accident-free your warehouses have been lately, that doesn’t necessarily prove that your safety measures are exemplary or even adequate. Instead, there’s always the chance that you’ve merely been lucky.

So don’t use a low rate of injury as an excuse to cut corners on your safety program or to skip your daily safety training.

And in case you’re looking for some good ideas on that, check out this month’s magically delicious (oops, we meant “detailed”) calendar of safety training topics. Trust us when we say that it’s far more effective than a rabbit’s foot.

Happy training – and Happy St. Patrick’s Day.

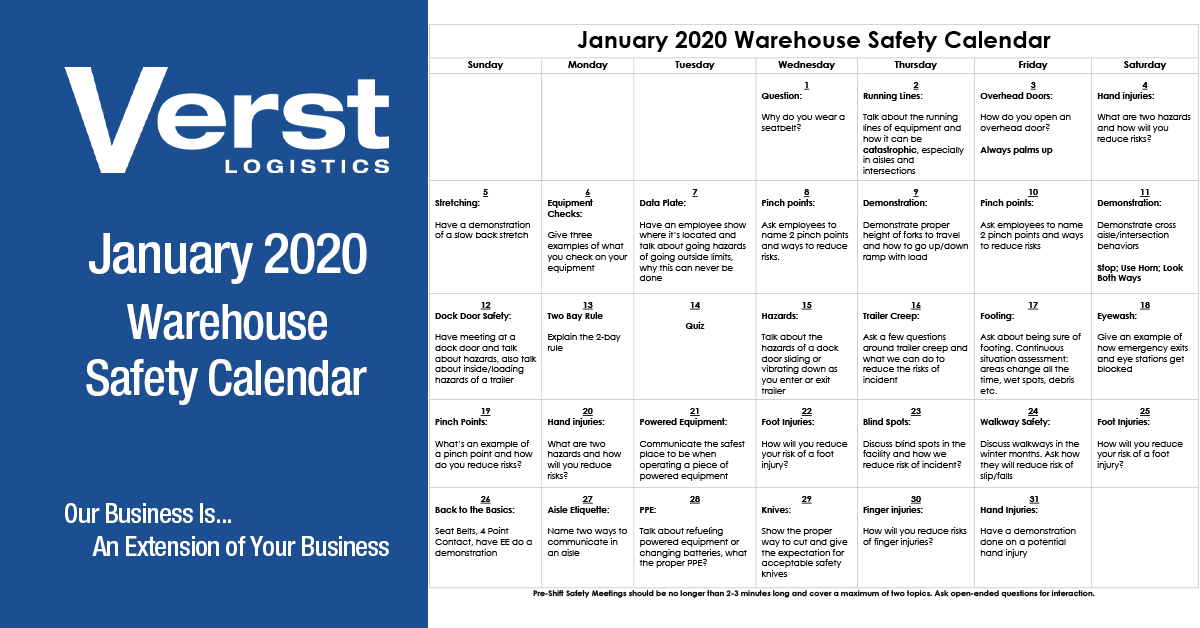

March 2020 Warehouse Safety Training Calendar & Meeting Topics for Discussion |

||||||

|

Sunday |

Monday |

Tuesday |

Wednesday |

Thursday |

Friday |

Saturday |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|

Hand Injuries: Tell me 2 ways to reduce hand injuries today? |

Intersections: Tell me three (3) things you must do at an intersection to reduce risks of incident? |

Falling Products: If a product is starting to fall, what should you do?

|

Stopping Equipment: Tell me two (2) things you must do when you stop your equipment to reduce risk of incident? |

Direction of Travel / Securing Product: Always look in direction of travel…. Tell me how you secure product on your equipment. |

Foot Injuries: Tell me three (3) ways to reduce the risk of foot injuries today? |

Inspections: Tell me three (3) items you must check on or around your equipment before use? |

|

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

Open Ended Question – Hazards: What hazards are in your area and how can we reduce them? Use a picture, object or go to area.

|

Hand Safety: Tell me two (2) ways you can injure you hand, how will you reduce risks? |

Pinch Points: Demonstrate two (2) pinch points in your working area. **Never put body parts outside equipment lines** |

Proper Lifting: Bring a case to pre-shift and have someone demonstrate proper lifting technique. Stress the importance of proper lifting. |

Footwear: Take a moment and look at employee footwear and discuss the importance of having good footwear when working.

|

Hydration: Select an associate and have them explain when and how they properly hydrate before starting work. Drink ½ body weight in oz |

Two-Bay Rule: Ask: What are overhead hazards? Discuss the 2 bay rule Show as a demonstration. |

|

15 |

16 |

17 |

18 |

19 |

20 |

21 |

|

Trailer Hazards: Ask questions around trailer hazards such as bulkheads, wet dock plate, damage to trailer. Also, stress stretching. . |

Powered Equipment: Demonstrate a safe way to operate powered equipment: 4 points, forks low, seatbelt, etc. |

Security: Talk about how unauthorized people can get into the facility and what’s in place to stop them. Ask whom you should report this to?

|

PPE Check: Have meeting in a PPE area or bring PPE to meeting and inspect as a group. Boots included.

|

Use Quiz

|

Dock Doors: Have meeting at the dock and discuss door hazards. Include never talking through door to drivers, etc. in your discussion |

Hand Safety: How can you pinch your fingers, what will you do to reduce risks?

|

|

22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

Reporting: Why is it important to report a hazard ASAP? Why is it important to report an incident / accident immediately? |

Seatbelts: Give three (3) reasons why we wear seatbelts? |

Fatal Risks: Ask: What are the three (3) fatal risks? Working on Heights, Trailer Pulls, LOTO. Discuss the last one that you heard about or occurred. |

Hand Safety: How can you pinch your fingers, what will you do to reduce risks?

|

Cell Phone Policy: Ask how they can be distracting.

Also, remind employees they must report injuries immediately. |

Horseplay: Discuss why horseplay is not allowed, and ask for example on how injuries can occur from horseplaying. |

MHE: Speak on the importance of completing an equipment checklist prior to using MHE. Cover with new LTO operators.

|

|

29 |

30 |

31 |

|

|

|

|

|

Dock Flow: Demonstrate dock flow and what must be done to achieve a safe ALARP day! |

Hydration: Select an associate and have them explain when and how they properly hydrate before starting work. Drink ½ body weight in oz |

Securing Product: Tell me how you secure product and what would you do if began falling? |

|

|

|

|

Tags:

Safety must always be a top priority because warehouses are of the most dangerous places to work in America. But how can those risks be mitigated in order to keep employees safe and to keep the...

Resources

Connect