December 31, 2019

Safety must always be a top priority because warehouses are of the most dangerous places to work in America. But how can those risks be mitigated in order to keep employees safe and to keep the operation running? Safety.

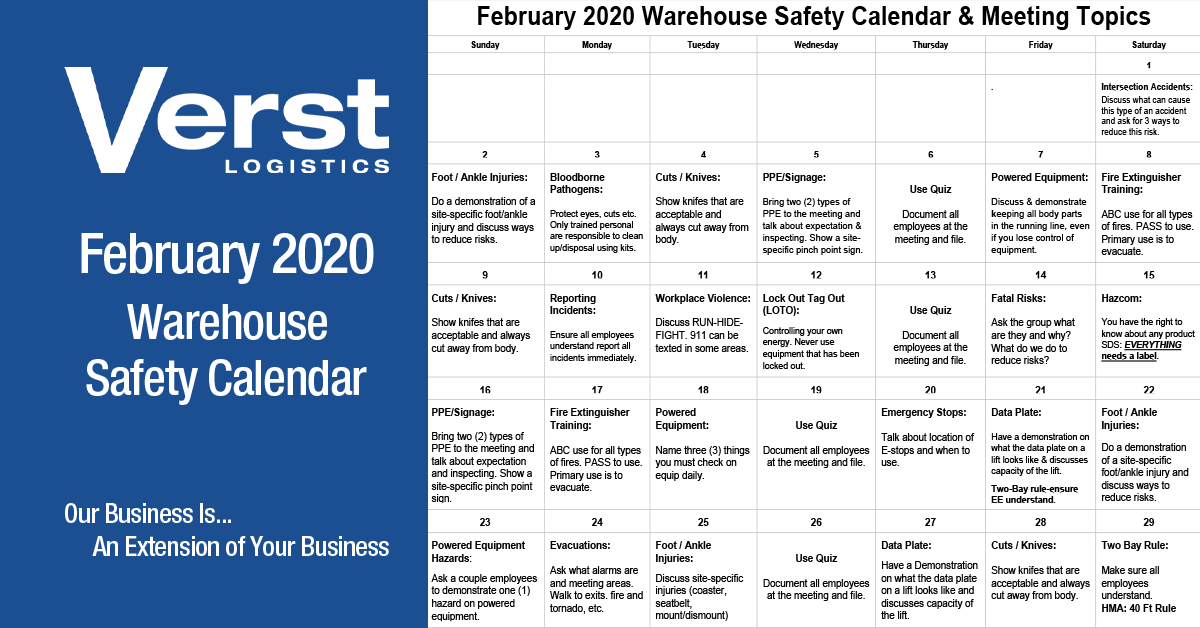

In an effort to keep operations running smoothly and employees safe, companies that put employees at risk should always enforce safety protocol such as safety moments or meeting at various times throughout the day. Feel free to view or download our January 2020 Warehouse Safety Calendar today, or view any of our past warehouse safety calendars to help keep your operations safe.

Take a look at 2018 U.S. Bureau of Labor’s report (official 2019 results not available yet) on individuals that work in the logistics industry and you will be shocked. Not only do injuries happen, they happen often, and they cost companies millions of dollars in revenue that could have been prevented through various safety training's and precautions taken by employees. The safety calendars we produce are meant to be used by a wide variety of industries, including but not limited to, transportation, warehousing, contract packaging, supply chain, manufacturing, construction, and so many more!

In 2018 alone, there 649,900 incidents reported that led to 608,400 documented injuries. However, many of these accidents were preventable and one of the ways to decrease employees’ risk is through safety & training. One of the best ways to make safety more personal and meaningful is to encourage all employees to speak during safety moments and apply safety training to their daily lives. The safety calendars we produce are meant to be used by a wide variety of industries, including but not limited to, transportation, warehousing, contract packaging, supply chain, manufacturing, construction, and so many more!

One of the biggest things we noticed over the last 5 years has been the number of injuries. The overall number of injuries and incidents in the transportation and warehousing industries have decreased year over year since 2014. These numbers are powerful and help us continue to produce warehouse safety calendars to empower managers to help keep their employees safe.

Not sure what to cover during your safety meetings? Feel free to ask us for help, or view any of our past warehouse safety calendars below the January 2020 Warehouse Safety Calendar.

Download the calendar here: 2020 Warehouse Safety Calendar

View the Safety Alert for the month of January: Knife Safety

January 2020 Warehouse Safety Calendar |

||||||

|

Sunday |

Monday |

Tuesday |

Wednesday |

Thursday |

Friday |

Saturday |

| 1 | 2 | 3 | 4 | |||

|

|

|

|

Question: Why do you wear a seat belt? |

Running Lines: Talk about the running lines of equipment and how it can be catastrophic, especially in aisles and intersections |

Overhead Doors: How do you open an overhead door? Always palms up |

Hand injuries: What are two hazards and how will you reduce risks? |

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|

Stretching: Have a demonstration of a slow back stretch

|

Equipment Checks: Give three examples of what you check on your equipment |

Data Plate: Have an employee show where it’s located and talk about going hazards of going outside limits, why this can never be done |

Pinch points: Ask employees to name 2 pinch points and ways to reduce risks |

Demonstration: Demonstrate proper height of forks to travel and how to go up/down ramp with load |

Pinch points: Ask employees to name 2 pinch points and ways to reduce risks |

Demonstration: Demonstrate cross aisle/intersection behaviors Stop; Use Horn; Look Both Ways |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

|

Dock Door Safety: Have meeting at a dock door and talk about hazards, also talk about inside/loading hazards of a trailer |

Two Bay Rule Explain the 2-bay rule |

|

Hazards: Talk about the hazards of a dock door sliding or vibrating down as you enter or exit trailer |

Trailer Creep: Ask a few questions around trailer creep and what we can do to reduce the risks of incident |

Footing: Ask about being sure of footing. Continuous situation assessment: areas change all the time, wet spots, debris, etc. |

Eyewash: Give an example of how emergency exits and eye stations get blocked |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

|

Pinch Points: What’s an example of a pinch point and how do you reduce risks?

|

Hand injuries: What are two hazards and how will you reduce risks? |

Powered Equipment: Communicate the safest place to be when operating a piece of powered equipment |

Foot Injuries: How will you reduce your risk of a foot injury?

|

Blind Spots: Discuss blind spots in the facility and how we reduce risk of incident? |

Walkway Safety: Discuss walkways in the winter months. Ask how they will reduce risk of slip/falls |

Foot Injuries: How will you reduce your risk of a foot injury? |

| 26 | 27 | 28 | 29 | 30 | 31 | |

|

Back to the Basics: Seat Belts, 4 Point Contact, have EE do a demonstration

|

Aisle Etiquette: Name two ways to communicate in an aisle |

PPE: Talk about refueling powered equipment or changing batteries, what the proper PPE? |

Knives: Show the proper way to cut and give the expectation for acceptable safety knives |

Finger injuries: How will you reduce risks of finger injuries?

|

Hand Injuries: Have a demonstration done on a potential hand injury |

|

Tags:

March 2020 Warehouse Safety - What’s Luck Got To Do With It? Raise your hand if you believe in leprechauns. How about the magic of four-leaf clovers? “Lucky” subjects like that are fun to think about...

29 Ideas For February Risk-Prevention Discussions: A Day-to-Day Warehouse Safety Calendar When most people think of risky careers, becoming a warehousing professional probably isn’t one of them. Yet...

Resources

Connect