September 19, 2018

Most businesses have lots of areas to improve in, especially in their warehouses, but if you don't upgrade and streamline business operations sooner rather than later, the outlook for your business is not efficient. Some of the effects of not streamlining operations results in bad habits, counterproductive practices, and a high cost of inventory.

Honestly, who likes to pay a higher price for the things you currently use? There's not anyone that comes to mind when I ask this question, so this is why we have come up with ten (10) inventory management best practices for your business. Year after year, your warehouse and operations will run smoothly and efficiently while running an effective business by following these ten inventory management best practices.

Inventory Management Best Practices

There are many inventory management best practices to follow, but there are general practices that every business can benefit from. Feel free to reach out and ask how we can help you and your business grow.

1) Categorize Your Inventory Using ABC AnalysisUtilizing the ABC analysis technique, you will be able to categorize your inventory into a hierarchy from most important items to least important items.

A-items: best selling, high-priority stock and require regular reordering and constant quality review

B-items: valuable, medium-priority stock that usually requires monthly reordering

C-items: low-priority stock that are typically carried in high-volumes with minimal reordering

Organizing your stock in your warehouse according to how much value they bring to your business and how they sell will help you optimize storage space and streamline order fulfillment.

2) Optimize Your Pick and Pack Process

Pick and pack processes are a set of procedures and tools that your employees use to fulfill customers' orders quickly and efficiently.

There are many types of these processes, such as discrete order picking, batch picking, wave picking and zone picking.

In order to optimize and achieve effective inventory management for the pick and pack process, below are five (5) ways to improve your process:

• Warehouse design optimization: place top-selling items closest to the packing station

• Well-organized warehouse: clean and remove clutter from every area

• Implement and utilize a warehouse management system (WMS): items will be listed in the order that the picker will find them.

• Double check each order for accurate counting

• Use barcodes or RFIDs: every piece of inventory will be labeled and easy to count

3) Create and Establish Your Inventory KPIs

Inventory KPIs measure performance over an amount of time towards a certain goal of a specific area. The tracking of KPIs allows your business to possess the data to make smart, strategic decisions for your business with clear milestones established every week, quarter, and year.

There are six (6) inventory KPIs that your business should focus on:

• Inventory Carrying Costs

• Inventory Write-off and Write-down

• Rate of Inventory Turnover

• Cycle Time

• Order Status and Tracking

• Fill Rate

4) Utilize Batch Tracking

Batch tracking is the process of tracing goods along the distribution chain using batch numbers. The word "batch" refers to a particular set of goods that were produced together and use the same materials.

The utilization of an automatic batch tracking system allows information to be input about all products within each batch. This tool is very beneficial in case of a product recall and you need to access where the products are located quickly.

5) Use an Accurate Reorder Point Formula

A reorder point formula does exactly what the name suggests - approximately telling one when to order more stock because your inventory has reached it's lowest sustainable point before you need more.

Using this proven mathematical equation, the reorder point formula will help you maintain the right stock levels in your warehouse each month.

Reorder Point = [(Average Daily Unit Sales)x(Average Lead Time in Days))] + Safety Stock

**This model suggests that the average daily unit sales are multiplied with the average lead time in days, then added with the amount of safety stock.

6) Carry Safety Stock Inventory

Safety stock inventory is a small, surplus amount of inventory kept on hand to guard against variability in market demand and lead times. Without this "safety net" of inventory, you can lose revenue, customers, and a potential loss of market share.

Secure all these benefits by carrying safety stock:

• Stockout prevention

• Protection against unexpected spikes in demand

• Compensation for inaccurate market forecasts

• A buffer for long-than-expected lead times

7) Optimize Inventory Turnover Rates

The inventory turnover rate (ITR) divides the cost of the goods sold (COGS) by the average inventory. Calculating the rate of inventory turnover allows a better grasp and understanding of the market demand for your products and what steps you need to take to sell or stock more inventory.

ITR = COGS / Average Inventory

Four (4) ways to increase your rate of inventory turnover:

• Experiment with pricing

• Liquidate obsolete stock

• Forecast customer demand

• Redistribute your inventory to other warehouses

8) Streamline Your Stocktake

The stocktaking process is the steps you take to count your inventory. When you are able to streamline this process, it will help you greatly reduce the possibility of making costly mistakes.

Having a well-structured stocktaking process allows your staff to work efficiently to uncover discrepancies and inaccuracies while keeping them focused and engaged on the topic at hand.

Here are four (4) ways to streamline your stocktake:

• Schedule your stocktakes to reduce impact on business operations

• Know what stock you’re counting and how you’re counting it

• Open and count absolutely everything – no guesswork allowed

• Clean and organize your stockroom before performing your stocktake

9) Reduce Your Inventory

The goal of reducing inventory levels is to find the "sweet spot", and no longer have 20-40% of the working capital tied up in inventory. The spot I am referring to is one where you have the lowest possible inventory levels without being overstocked in order to maximize growth and profitability for your business.

Here are three (3) inventory reduction methods you can follow:

• Lower Lead Times

In order to achieve this, you must track your existing lead times, sharing sales data with suppliers and reduce your minimum order quantities (MOQs)

• Eliminate Inventory No Longer Used

You can achieve this by reworking or modifying your stock, offering a discount, liquidating the stock, or dating it for a tax write-off

• Improve Inventory Forecating

You can achieve this through real-time tracking, monitoring and reporting, integrated communication, and large volume inventory management tools

10) Use a Cloud-Based Inventory management System

One of the best decisions you will ever make is not using Excel to manage your inventory because it is designed for running a small business with little growth.

If you want to expand and grow, you need to utilize a cloud-based inventory management software that allows you to pay for the features you need now and seamlessly upgrade when you need to in the future.

On top of stress-free upgrades, cloud software companies work in the background to make sure things continue to run smoothly, and should you need any questions answered or breaks fixed, they’ll have a support team standing by to assist you.

**11) A Bonus Inventory Management Best Practice

#10 is not just a best practice, but something that ties all of the other best practices together. A cloud-based inventory management software helps improve every area of your business operations.

At least, that's what our software does for our business.

If you're seeking solutions to solve your inventory management crisis and want to optimize inventory processes, contact the Verst fulfillment team and see how outsourcing and our technology can better serve your business to allow you to grow with no restraints.

Tags:

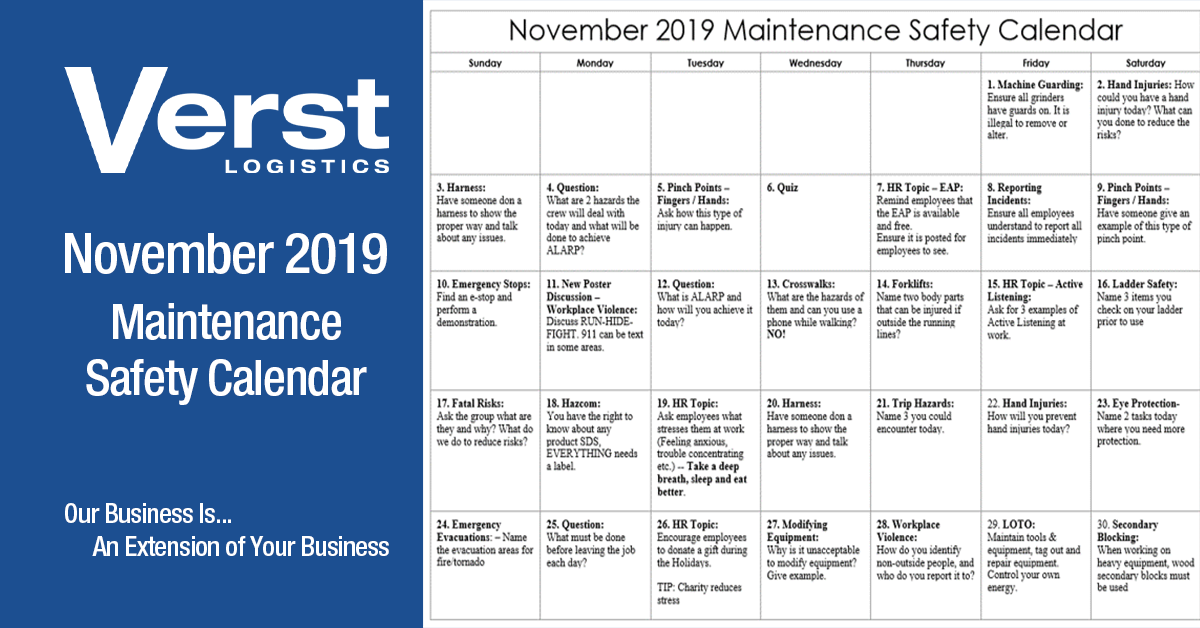

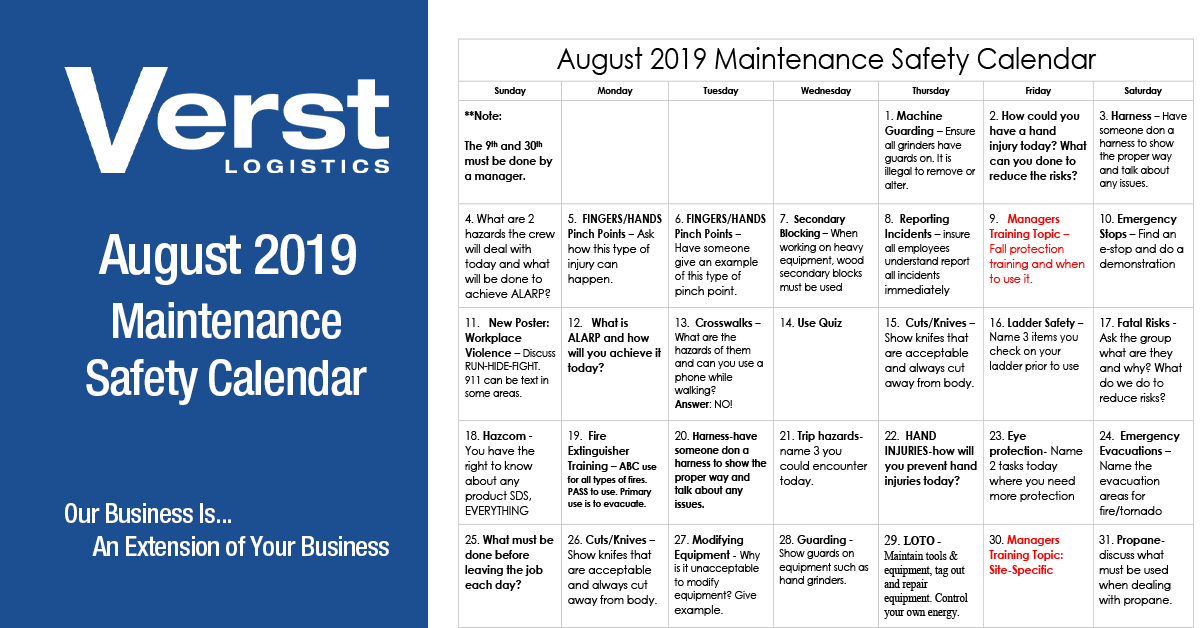

Regular maintenance is required to keep all equipment, machines and the work environment safe and reliable at all times in the warehouse. Dangerous situations, accidents and health problems can occur...

Regular maintenance is required to keep all equipment, machines and the work environment safe and reliable at all times in the warehouse. Dangerous situations, accidents and health problems can occur...

Resources

Connect